A PRINTORTHESE® is an orthotic device printed on a 3D printer.

Thanks to SimBrace® we can simulate your orthosis before we produce it.

Make an appointment over the phone or send us a message!

PRINTORTHESE®

3D-printed orthoses

3D printing is becoming increasingly more popular in the field of technical orthopedics. When using 3D printing technology, orthoses are first digitally designed and then printed layer by layer.

Our PRINTORTHESE®, created using 3D printing technology, is an aestically pleasing device that offers state-of-the-art functionality while accounting for your anatomical requirements. The design possibilities of the PRINTORTHESE® are endless. You can personalize your PRINTORTHESE® any way you want. Accessories such as watches, fitness trackers, lights, rhinestones, and emblems can be easily integrated into the orthosis. In this way, your medical device becomes a functional piece of jewelry that is no longer hidden from your everyday life, but rather proudly presented.

How it all began...

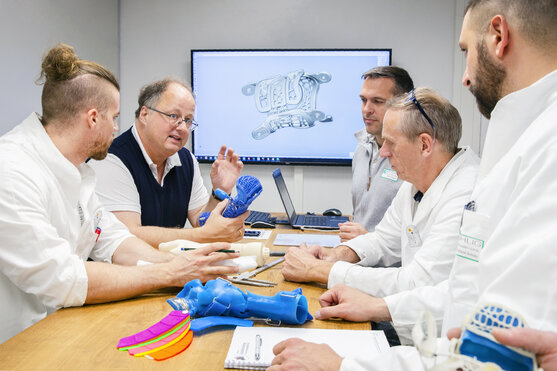

A few years ago, we began to rethink and redesign our orthoses with the intention of integrating new properties that would improve the overall orthotic experience for our patients. We continue to focus on making the orthoses as comfortable as possible, improving the overall design, and achieving our functional and therapeutic goals.

The PRINTORTHESE® is the culmination of many years of research and development in the realm of 3D printing technology. This 3D printed device satisfies all requirements we have of modern orthoses.

Scan and simulate

Thanks to 3D printing technology, we are able to perform a 3D scan instead of traditional plaster casts to capture the shape of the body parted being treated. The advantage of this procedure is that the correction of the arm, spine etc. can be simulated during the scan (SimBrace® procedure). Using this patented process, we can verify that the patient is actually showing an improved functional result in a defined correction before the orthosis is completed.

The orthosis is then designed based on the scan model in a virtual environment and then produced using 3D printing technology.

Why 3D print?

The PRINTORTHESE® offers numerous advantages:

- scanning technology instead of plaster casts

- lower weight due to more open spaces (perforations)

- reduced perspiration due to breathability

- padding of possible pressure load zones achieved by integrated gel pads

- improved tactile perception

- customization by the patient (choice of color and design)

Although the orthosis is 3D printed, we still use traditional production and fitting methods to ensure we achieve the best fit. Initial studies show that the acceptance of the PRINTORTHESE® is relatively high compared to orthoses made with conventional PE technology. These studies also showed that patients with PRINTORTHESE® use the affected hand more frequently for manual activities and report greater wearing comfort.

Let yourself be inspired! We accompany many interesting patients during their Pohlig appointment and give you personal insights.

For those who want to delve even deeper into the matter, we have a suitable video for almost every supply area.

Take a look behind the scenes at Pohlig and find out about diagnoses and our innovative aid solutions!